Polyamide cagesdeliver stiffness, flexibility and oil resistance in ball bearings

Polyamide (PA) is playing a key role inenhancing fuel economy through its usage as cage material for tandem pinionball bearings in passenger car axles including the one in the 2013 Ford C520Escape. The 30% glass fiber-reinforced grade Stanyl TW200F6 PA46 from DSMEngineering Plastics (Birmingham, MI) contributes to a 1.5% saving in fuelconsumption compared with an all-steel tapered roller bearings.

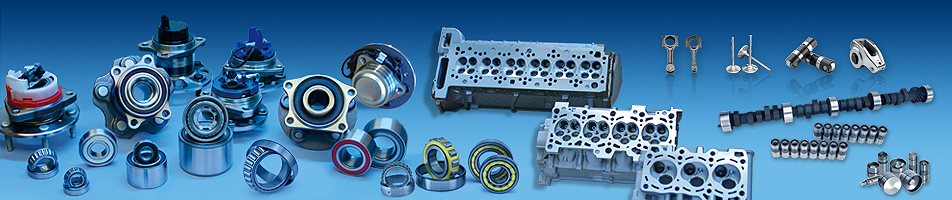

Polyamide cages facilitate design ofenergy-efficient auto bearings

In total, four Ford vehicles, twoChrysler vehicles and GM’s Cadillac ATS utilize the injection-molded bearings,with GM also planning to use them on truck axles and differentials starting inthe spring of 2013. The tandem ball bearings are manufactured by SchaefflerTechnologies (Herzogenaurach, Germany).

In automotive differential, axle andpower take-off (PTO) applications, steel cages are traditionally used in taperroller bearings. “Metal is used in the cages of these all steel solutions dueto strength and chemical resistance to hypoid gear oil,” says Bill Burnham,Business Development Manager, Powertrains, at DSM Engineering Plastics. “Thistype of oil is typically quite aggressive upon most plastic materials.”

For the more energy-efficient tandemball bearings, however, the cost position at which they must compete precludedthe use of a steel cage. Tandem ball bearings are more efficient on account ofthe lower rolling resistance of ball bearings (less contact area) versus rollerbearings.

“Stanyl TW200F6, [however], demonstratedacceptable resistance to Hypoid Gear oil up to 150°C, as well as an appropriatebalance of stiffness and flexibility necessary to insert the ball bearings intothe cage and retain them,” says Burnham. Dimensional stability was also afactor in material selection.

Currently 12 different cages have been developed for usein these tandem bearings with sizes ranges from 30 to 70 mm in diameter. Themass of each cage ranges from 5 to 9 grams. This new bearing work as drop-inreplacements for all tapered roller bearings.

技术支持

技术支持